Customizable Composite Packaging Bags – Factory Direct Transparent Plastic Bags for Clothing, Jewelry & Socks

In today’s competitive retail landscape, first impressions are everything. Before a customer touches your product, they’ve already formed an opinion—based on its packaging. That’s why modern brands, from indie labels to fast-growing e-commerce stores, are quietly shifting away from generic plastic wraps toward smarter, more sophisticated solutions. Enter the era of customizable composite packaging bags: where transparency meets strength, and branding begins at the very first touchpoint.

Why Modern Brands Are Rethinking Their Packaging Strategy

It starts with psychology. Studies show that consumers form judgments about product quality within seconds of seeing the packaging. A flimsy, cloudy bag suggests low value—even if the item inside is exceptional. On the other hand, a crystal-clear, well-structured composite bag signals care, professionalism, and attention to detail.

The evolution from basic PE (polyethylene) bags to multi-layered composite materials marks a turning point in retail packaging. No longer just about containment, today’s bags must protect, promote, and impress. Transparency allows instant product visibility, reducing hesitation at checkout. Durability ensures garments, delicate jewelry, or folded sock sets arrive pristine. And customization turns every package into a branded moment customers remember.

The Hidden Strength Behind Lightweight Clarity

Don’t let their lightness fool you—composite packaging bags are engineered for performance. Unlike single-layer plastics, these bags combine multiple films such as PET, AL, and CPP, each contributing unique benefits. The result? Superior puncture resistance, moisture barriers, and optical clarity that stays sharp over time.

For clothing brands, this means no more snagged hems or damp-stained fabrics during transit. For jewelers, anti-tarnish properties and static control keep delicate pieces looking showroom-fresh. And because these materials resist tearing even under stress, returns due to damaged packaging drop significantly—protecting both your margins and reputation.

Democratizing Customization: Small Batches, Big Impact

Gone are the days when only luxury labels could afford tailor-made packaging. With direct-from-factory production, small and mid-sized businesses can now access the same level of customization—without minimum order constraints.

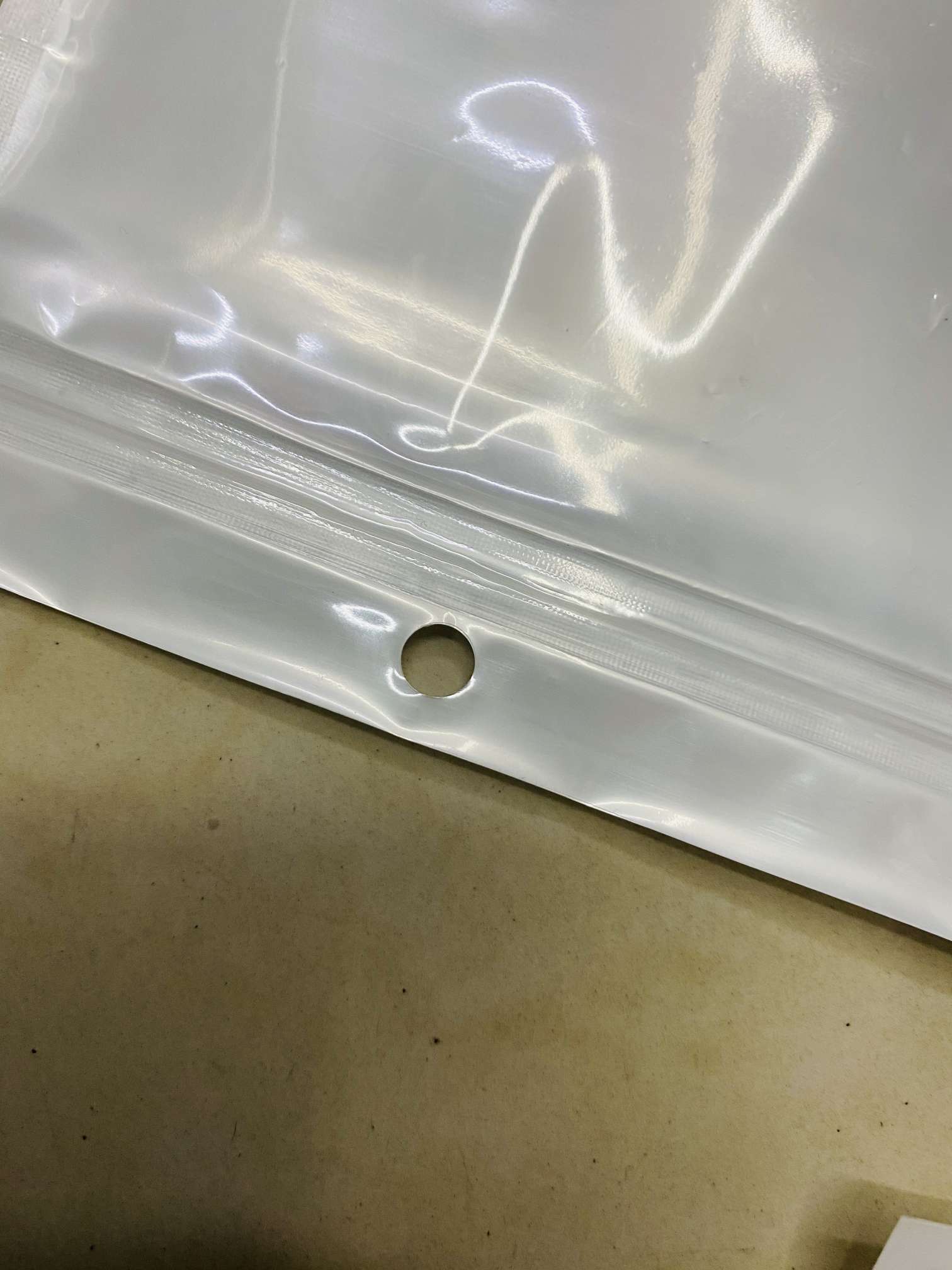

Whether you need a narrow sleeve for a silk scarf or a wider pouch for bundled socks, dimensions can be fine-tuned to fit your inventory. Choose thickness levels based on fragility, select resealable zippers or spot-seal closures, and add design elements like metallic foil logos, colored header strips, or die-cut windows that showcase your product without opening the bag.

For sock brands, consider built-in compartment dividers—perfect for presenting matching sets side-by-side. It’s not just functional; it transforms how products display in warehouses, on shelves, and in social media unboxings.

Factory Direct = Value Without Compromise

By cutting out middlemen, we deliver high-performance packaging at prices that support healthy margins. Whether you're testing a new line with a limited run or preparing for wholesale distribution, our model supports both agility and economy.

Need 500 units tomorrow? We can do that. Planning a 50,000-unit launch next month? Our production lines scale seamlessly. Faster turnaround times mean quicker go-to-market cycles—critical in fashion, where trends shift overnight.

Packaging That Works as Hard as You Do—From Shelf to Doorstep

A transparent composite bag does more than look good—it streamlines operations. Visual verification reduces packing errors, especially crucial during peak seasons. Point-break seals allow easy customer access while ensuring tamper evidence, building trust from the moment the package is received.

And for growing brands investing in automation, these bags are compatible with semi-automated packing systems. Consistent sizing and sturdy structure mean fewer jams and higher throughput—helping small teams achieve big efficiency.

Your Brand’s Silent Ambassador

Every unboxing is a storytelling opportunity. When a customer peels back the seal on a bag adorned with your logo in elegant gold foil, they’re not just opening a product—they’re experiencing your brand ethos.

Take the case of a boutique jewelry label that switched to custom composite bags with integrated QR codes linking to craftsmanship videos. Not only did return rates fall by 30%, but repeat purchases increased by nearly half within three months. Why? Because the packaging made them feel connected.

Further enhancements—like built-in loops for hangtags or dedicated zones for promotional inserts—turn each bag into a compact marketing toolkit. Every inch serves a purpose.

Sustainable by Design, Practical by Nature

True sustainability isn’t just about biodegradability—it’s about longevity. A stronger bag breaks less often, meaning fewer replacements, lower carbon footprint, and reduced waste. While our composite materials are currently recyclable through specialized streams, their real environmental win lies in prevention: one intact delivery beats ten failed ones.

Brands using these bags report fewer complaints, fewer reshipments, and a cleaner logistical trail. In balancing aesthetics, function, and responsibility, composite packaging emerges not as a compromise—but as a forward-thinking choice.

Upgrade your presentation. Protect your products. Tell your story—every time a customer opens their order. With customizable, factory-direct composite bags, your brand doesn’t just ship. It arrives.